Many medical products have strict cleanliness requirements requiring specific ISO-certified hygienic production requirements. To meet these requirements, JOEY has an ISO class 8 cleanroom with both single-shot and two-shot LSR production lines where we also perform post-molding value-added processes.

Production Capabilities

Single-shot molding: In this molding process, only one LSR material is used for injection molding parts.

Multi-shot molding: LSR is combined with two or more polymers or a polymer and substrate in this process for more complex components.

Overmolding: In overmolding, the liquid silicone rubber is molded around a substrate or finished component.

Micromolding: This injection molding process produces tiny, complex parts, typically with a shot weight of less than 1 gram.

Hygienic molding: LSR parts are produced in a clean, hygienic environment that are highly-controlled to various levels, such as white rooms or more stringent ISO cleanrooms with various classifications.

LIM or LSR molding: Liquid Silicone Rubber (LSR) molding is the process used to create robust, pliable, high-precision, high-quality parts in large numbers.

Liquid Silicone Injection Molding produces parts that are highly water repellent and resistant. As such, coupled with the precise nature of their sizing, they’re ideal for use as seals, membranes, electrical connectors, and a variety of other medical, commercial and domestic applications.

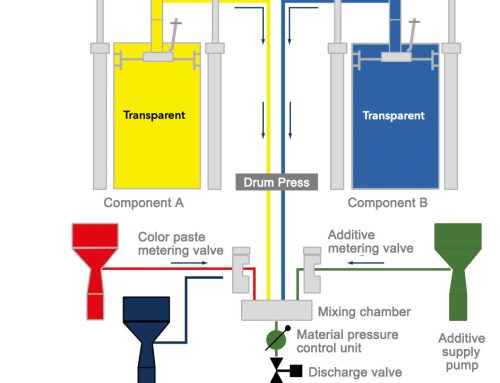

Liquid injection molding, or LIM, is a production process commonly used to make silicone products or to make products that need to withstand extreme conditions, regardless of the industry. The process is an injection molding process at the heart, meaning that materials are injected into a pre-made mold, where they’re then left to sit and curate. Then, the process repeats itself until the part run is complete.

Our state-of-the-art facility is climate-controlled and exceptionally clean. Our production areas are clean and because our LSR, LSR 2k, multi-shot and overmolding manufacturing cells are fully-automated, there is minimal human contact.