Mold Making for Compression / Injection Molding

Joey works with many customers to provide mold design assistance for liquid injection molding (LIM). With vast experience in mold design and engineering, including liquid silicone rubber (LSR) materials selection knowledge, mechanical engineering services on staff, and familiarity with many industries and applications, Stockwell Elastomerics is uniquely qualified to provide mold design support to customers as needed. Stockwell Elastomerics utilizes the top performing liquid silicone rubber materials and manufactures custom molded silicone parts and components using liquid silicone rubber with liquid injection molding.

Mold designing

Designing molding according to the client’s ideas and a team of designers and engineers with more than 15 years of experience providing professional advice to ensure that the final product meets the client’s specifications and any regulatory requirements that may apply. By working in close contact with customers and manufacturing high quality silicone products that meet their needs and specifications.

In-house tool shop

Joey’s in-house tool shop consists of 21 latest state-of-the-art 3-axis CNC machines and 5 EDM machines. We can make your silicone products tooling with initial precision tooling and any future adjustments in our tooling workshop, meaning mold adjustments are more cost-effective and turnaround times shorter. Our machinists with decades of experience not only provide unparalleled insight into mold design, but are more cost-effective and time-effective after adjusting mold creation in our in-house work-shop.

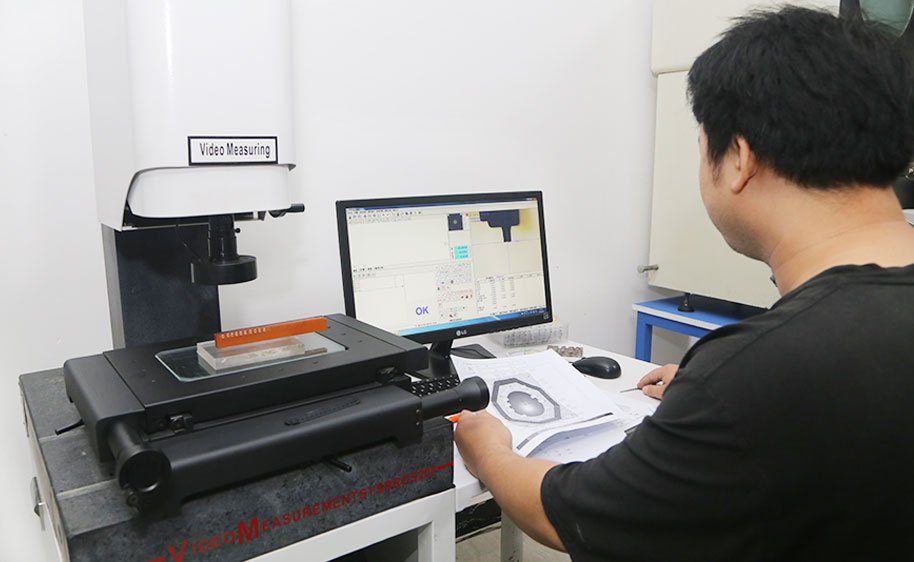

Video Measuring

The video measuring system uses advanced software and hardware to capture high-resolution images and analyze them to quickly and accurately measure dimensions such as length, width, height, angle, and curvature. This helps to reduce errors and increase efficiency in the production process, leading to improved quality control and faster turnaround times. Additionally, the video measuring system can identify defects and inconsistencies in the silicone tool, allowing for adjustments to be made before production begins.